Juki DLN-9010-7S, 7H Direct Drive High Speed Needle Feed Lockstitch Industrial Sewing Machine DLN9010, AutoTack, Trim, Foot Lift, Table&Stand 5000SPM

For Industrial Use

| See below

Call for Availability and Pricing |

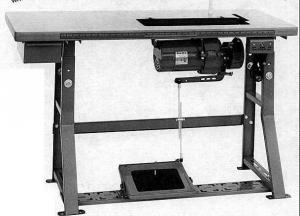

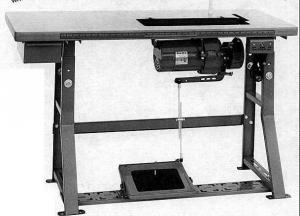

Assembled Power Stand, Program Panel on Top of Machine, Built In Direct Drive DC Servo Motor, Metal Stand, Adjustable Height , Wood Top 48" W x 20" D

This is the Juki DLN-9010, a needle-feed type DDL-9000 Series sewing machine, that has been highly applauded as the top-of-the-line lockstitch machine with a thread trimmer. It has inherited the advanced features of the DDL-9000 Series, such as the direct-drive system, semi-long arm and elimination of the oil pan. In addition, it comes with a highly reliable needle feed mechanism. The needle feed mechanism responds to a wide range of applications such as the sewing of outerwear, runstitching of menís shirts, etc. and the attaching of various parts to garment bodies.

More Juki DLN-9010 Features:

The machine ensures accurate stitch pitches (stitch length) as well as preventing slippage of the upper cloth thanks to the needle-feed mechanism which offers excellent efficiency of feed.

The bottom feed's locus has been improved to match the needle feed motion, thus the machine produces beautiful seams without stitch gathering, even when it is used for sewing slippery and difficult-to-feed material or for handling a difficult process.

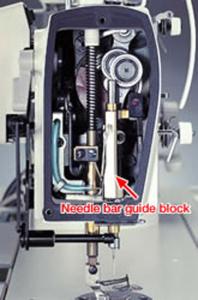

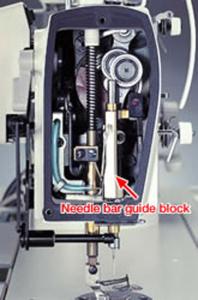

The needle feed mechanism is a so-called "dry type", which does not require oiling. With this mechanism, a highly reliable machine structure, free from oil leakage troubles, has been achieved. The frame, which requires only a minute quantity of lubricating oil, is structured to eliminate oil leakage.

The machine can be easily changed over from a needle feed machine to a bottom feed machine, through a simple adjustment and gauge replacement. It is a useful feature for those users who also want to use the machine simply as a regular bottom feed type machine in accordance with applications and processes.

A horizontal-type automatic thread trimmer mechanism ensures speedy and reliable thread trimming.

The hinge has been moved 10cm behind the needle entry point to ensure the material won't be caught, thus contributing to upgraded workability.

MODEL NAME : DLN-9010SS DLN-9010SH

Application: For light- to medium-weight materials For heavy weight materials

Max. sewing speed: 5,000rpm 4,000rpm

Max. stitch length: 4.5mm*

Needle bar stroke : 33mm

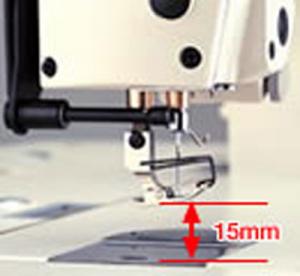

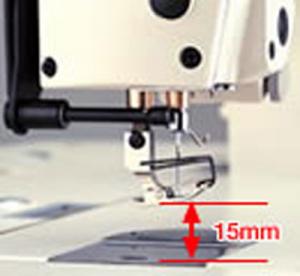

Lift of the presser foot

By hand: 5.5mm, By knee: 15mm(max.), Auto: 10mm

Needle (at the time of delivery): DB1(#11) #9 - #18

For JE:134 (Nm90) Nm65

Nm110 DB1(#21) #20 - #23

For JE:134 (Nm130) Nm120

Nm160

Hook: Automatic-lubricating full-rotary hook

Lubrication: Minute-quantity lubrication to needle bar and hook

Lubricating oil: JUKI New Defrix Oil No.1(equivalent to ISO VG7)

Distance from needle to machine arm: 300mm

Size of bed :517mm178mm

Bobbin thread winder: Built-in the machine head

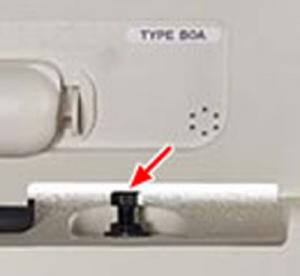

Micro-lifter screw :Provided as standard

Machine head drive: Compact-sized AC servomotor that is directly connected to the main shaft (direct-drive system)

Automatic reverse feed function: Provided as standard (built-in solenoid type)

Power requirement/Power consumption: Single-phase 100

120V, 200

240V, 3-phase 200

240V / 650VA

Total weight: 87kg

*The maximum sewing speed is 4,000 rpm or less in cases where the maximum stitch length is 3.5 mm or more.

Instruction manual

Needles

Bobbins

It comes complete with sewing machine table (size 48" x 20") and motor ( servo motor has 1/2 horse power, phase I, 110 volt), everything (drawer, belt, tools and instruction manual), packed in factory sealed boxes and never been used before.Professional assembly required.

© 2015 Sewmark Sewing Machine

Sewmark Sewing Machines

Sewmark Sewing Machines